Description

<br />

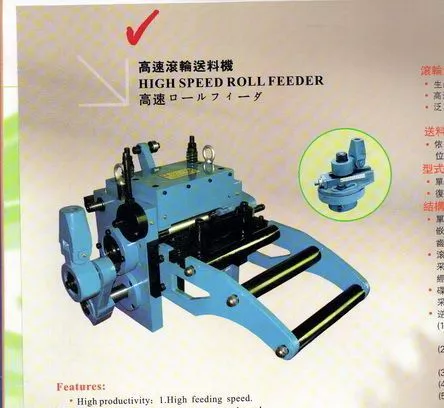

Features:<br />

<br />

High productivity:<br />

High feeding speed.<br />

Multistage in each stroke.<br />

High speed:SPM600.<br />

Universal:Easily adjustable for different thickness And width material.<br />

Practical and economical with simple mechanism.<br />

Easy maintenance with little error.<br />

<br />

Feeding Accuracy:<br />

Depending on feed length of stock and stroke of press,the general accuracy of the machine is within 0.05mm and would be as accurate as 0.01mm by pilot pin with automatic positioning system.<br />

Type:<br />

<br />

Single Type:for cutting stock at certain length or coiling back the finished products.<br />

Double Type:for there is any stuff left after stamping,and for short or thin stock.<br />

<br />

<br />

Mechanism Features:<br />

<br />

One Direction Clutch<br />

Made of tungsten carbide steel on the contacting surface to Keep rigidity,precision and durability.<br />

The gear is hardened to HRC60 o and ground to the best Transmission accuracy.<br />

Rooler<br />

High feed accuracy at exact positioning with hollow roller of less weight,and lower inertia.<br />

Disk Brake<br />

Apply the advanced brake lining to have accuracy,durability,and rigidity.<br />

The Anti-reversing Device<br />

The structure is the same with the one way clutch.It can precisely control the lower roller which will not reverse even in long time using.It is stable and precise.<br />

The brakes will be not out of control by the splashed waste oil when it is punching otherwise the lower roller will reverse and transfer distance will be imprecise.<br />

It will not caues high heat.<br />

Durable with super hard carbide surface and rollers.<br />

The acting rorm of the rollers is circular movement,unlike the four guides moving in Straight line,so it will not stuck.<br />

As less friction it will ocurred,the torsion needed will be correspondingly less.And the Transfer structure will not easily wear out.<br />

Speed can reach 30M/min if the anti-reversing device is fitted .Generally it is 20M/min.<br />

Its special structure can increased it is using life.<br />

<br />

<br />

Specifications<br />

ModelsRoll Width(mm)FeelLength(mm)Material Line height(mm)Material Thickness(mm)Press Capacity (T)Weight(Kg)<br />

<br />

RFS-105NS100500-1.660-1405-2064<br />

RFS-205NS200500-1.655-1002087<br />

RFS-255NS250500-1.655-1002095<br />

RFS-305NS300500-1.655-10040103<br />

RFS-355NS350500-1.655-10040111<br />

RFS-405NS400500-1.655-10060121<br />

RFS-455NS450500-1.655-10080131<br />

RFS-505NS500500-1.655-10080141<br />

RFS-555NS550500-1.655-100110151<br />

RFS-605NS600500-1.655-100110161<br />

RFS-138NS130800-1.664-16010-6076<br />

RFS-188NS180800-1.660-12020-6084<br />

RFS-1310NS1301000-3.570-14040-60142<br />

RFS-1510NS1501000-3.570-19540-60150<br />

RFS-2010NS2001000-3.580-20540-80155<br />

RFS-3010NS3001000-3.570-14060-160180<br />

RFS-4010NS4001000-3.570-14080-260200<br />

RFS-5010NS5001000-3.570-140110-260220<br />

RFS-6010NS6001000-3.570-140160-260240<br />

RFS-7010NS7001000-3.570-140160-260260<br />

RFS-1315NS1301500-3.570-14040-60143<br />

RFS-2015NS2001500-3.570-14040-80156<br />

RFS-3015NS3001500-3.570-14060-160181<br />

RFS-4015NS4001500-3.570-14080-260201<br />

RFS-5015NS5001500-3.570-140110-260221<br />

RFS-6015NS6001500-3.570-140160-260241<br />

RFS-7015NS7001500-3.570-140160-260261<br />

RFS-1320NS1302000-3.570-14040-60146<br />

RFS-2020NS2002000-3.570-14040-80159<br />

RFS-3020NS3002000-3.570-14060-160184<br />

RFS-4020NS4002000-3.570-14080-260204<br />

RFS-5020NS5002000-3.570-140110-260224<br />

RFS-6020NS6002000-3.570-140160-260224<br />

RFS-7020NS7002000-3.570-140160-260264<br />

RFS-2030NS2003000-3.5100-19060-160223<br />

RFS-3030NS3003000-3.5100-19080-200251<br />

RFS-4030NS4003000-3.5200-33580-200279<br />

RFS-5030NS5003000-3.5100-190110-260307<br />

RFS-6030NS6003000-3.5100-190110-260335<br />

RFS-7030NS7003000-3.5100-190110-260363<br />

*Right of modification reserved.<br />

*All specifications,dimensions and design characteristics shown in this page are subject to rechange without notice.

- feeder

- feeding machine

- straightener

- uncoiler

- decoiler

- straightening machine

- press machine

- hardware

- metal products

Production Capacity:

www.mzfeeder.com

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

Packaging Details:

Features:

High productivity:

High feeding speed.

Multistage in each stroke.

High speed:SPM600.

Universal:Easily adjustable for different thickness And width material.

Practical and economical with simple mechanism.

Easy maintenance with little error.

Feeding Accuracy:

Depending on feed length of stock and stroke of press,the general accuracy of the machine is within 0.05mm and would be as accurate as 0.01mm by pilot pin with automatic positioning system.

Type:

Single Type:for cutting stock at certain length or coiling back the finished products.

Double Type:for there is any stuff left after stamping,and for short or thin stock.

Mechanism Features:

One Direction Clutch

Made of tungsten carbide steel on the contacting surface to Keep rigidity,precision and durability.

The gear is hardened to HRC60 o and ground to the best Transmission accuracy.

Rooler

High feed accuracy at exact positioning with hollow roller of less weight,and lower inertia.

Disk Brake

Apply the advanced brake lining to have accuracy,durability,and rigidity.

The Anti-reversing Device

The structure is the same with the one way clutch.It can precisely control the lower roller which will not reverse even in long time using.It is stable and precise.

The brakes will be not out of control by the splashed waste oil when it is punching otherwise the lower roller will reverse and transfer distance will be imprecise.

It will not caues high heat.

Durable with super hard carbide surface and rollers.

The acting rorm of the rollers is circular movement,unlike the four guides moving in Straight line,so it will not stuck.

As less friction it will ocurred,the torsion needed will be correspondingly less.And the Transfer structure will not easily wear out.

Speed can reach 30M/min if the anti-reversing device is fitted .Generally it is 20M/min.

Its special structure can increased it is using life.

Specifications

ModelsRoll Width(mm)FeelLength(mm)Material Line height(mm)Material Thickness(mm)Press Capacity (T)Weight(Kg)

RFS-105NS100500-1.660-1405-2064

RFS-205NS200500-1.655-1002087

RFS-255NS250500-1.655-1002095

RFS-305NS300500-1.655-10040103

RFS-355NS350500-1.655-10040111

RFS-405NS400500-1.655-10060121

RFS-455NS450500-1.655-10080131

RFS-505NS500500-1.655-10080141

RFS-555NS550500-1.655-100110151

RFS-605NS600500-1.655-100110161

RFS-138NS130800-1.664-16010-6076

RFS-188NS180800-1.660-12020-6084

RFS-1310NS1301000-3.570-14040-60142

RFS-1510NS1501000-3.570-19540-60150

RFS-2010NS2001000-3.580-20540-80155

RFS-3010NS3001000-3.570-14060-160180

RFS-4010NS4001000-3.570-14080-260200

RFS-5010NS5001000-3.570-140110-260220

RFS-6010NS6001000-3.570-140160-260240

RFS-7010NS7001000-3.570-140160-260260

RFS-1315NS1301500-3.570-14040-60143

RFS-2015NS2001500-3.570-14040-80156

RFS-3015NS3001500-3.570-14060-160181

RFS-4015NS4001500-3.570-14080-260201

RFS-5015NS5001500-3.570-140110-260221

RFS-6015NS6001500-3.570-140160-260241

RFS-7015NS7001500-3.570-140160-260261

RFS-1320NS1302000-3.570-14040-60146

RFS-2020NS2002000-3.570-14040-80159

RFS-3020NS3002000-3.570-14060-160184

RFS-4020NS4002000-3.570-14080-260204

RFS-5020NS5002000-3.570-140110-260224

RFS-6020NS6002000-3.570-140160-260224

RFS-7020NS7002000-3.570-140160-260264

RFS-2030NS2003000-3.5100-19060-160223

RFS-3030NS3003000-3.5100-19080-200251

RFS-4030NS4003000-3.5200-33580-200279

RFS-5030NS5003000-3.5100-190110-260307

RFS-6030NS6003000-3.5100-190110-260335

RFS-7030NS7003000-3.5100-190110-260363

*Right of modification reserved.

*All specifications,dimensions and design characteristics shown in this page are subject to rechange without notice.www.mzfeeder.com

More about

Suzhou Ming Zhong Machinery Co., Ltd.

50-100

Employees

1M - 2M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- feeder

- feeding machine

- straightener

- uncoiler

- decoiler

- straightening machine

- press machine

- hardware

- metal products Ver Mais

Contact and location

-

Tan Tom

-

+86 512 xxxxxxxx

-

Suzhou / Jiangsu | China