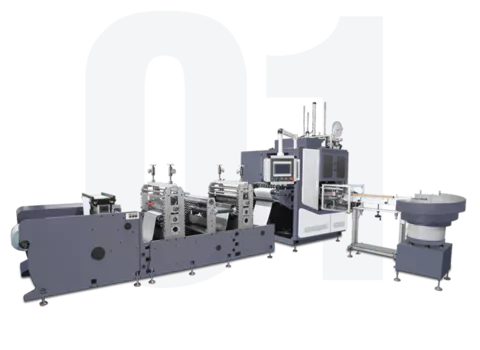

Description

1. The die-cutting seat is an independent high-precision wallboard, which is different from the traditional bottom roller wallboard

2. The die-cutting adopts a three-roller structure, which greatly reduces the runout of the magnetic roller, and can realize the stable and high-speed operation of 35g bottom paper at 150 m/min

3. High speed and stability, 3 finished products can be produced in one minute

4. THE HOOK ARM LIFTING METHOD IS USED FOR UNWINDING, AND THE MAXIMUM ROLL DIAMETER OF UNWINDING IS 750MM, AND THERE IS NO NEED TO MANUALLY LIFT

5. The whole machine is controlled by all servos, and the functions of automatic meter counting and automatic counting of finished roll output are realized

6. The vibrating plate can be optionally equipped to realize automatic core threading and automatic operation

- Glue-free

- high-speed

- automatic metering

- stable

Production Capacity:

20

Delivery Timeframe:

Within 45 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

Packaging Details:

fumigation wooden box

More about

Hengming Machinery

10-50

Employees

200K - 500K

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Rewinder

- no gluing

- no reverse folding

- automatic winding

Contact and location

-

yunchao Huang

-

+86 xxxxxxxx

-

温州市 / 浙江省 | China