Description

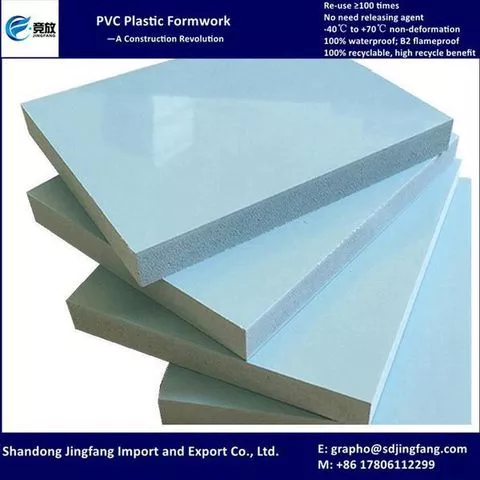

PVC Plastic formwork---A Construction Revolution

Re-use over 50times

100 % recyclable

100 % waterproof

B2-grade flameproof

No need releasing agent

40℃ to +70℃ non-deformation

Anti-corrosion, acid-proof, alkali-proof

What is PVC plastic formwork?

A new type of plastic formwork, which is made of PVC material only. It is a different product with traditional GMT or WPC, and is the first and world leader in the world. It can completely replace the traditional types of formwork, especially the plywood /timber formwork. Now is well popular with many markets.

100% recyclable , can re-use over 50-100times, B2 grade flameproof, 100% waterproof, no need demoulding agent, etc. It is a new revolution in the construction engineering formwork materials. Because of its prominent performance, it can effectively utilize waste resources, thus saving a lot of resources for country, which plays a huge role in protecting environment, optimizing environment and reducing carbon emission.

Its development is in accordance with the requirement of national energy conservation and environmental protection, adapt to the developing direction of the country industrial policy. Energy-saving with its environmental protection, and economic with its cyclic regeneration. This product will gradually replaces the traditional formwork in the building formwork field.

Standard size range:

Width: 915mm; 1200mm; 1220mm

Length: 1830mm~3600mm

Thickness: 10-22mm

The most popular size is 915*1830*14/15mm (China market) and 1220*2440*18mm( international market).

Other special sizes can be customized.

Performances of PVC plastic formwork

01 . Can re-use ≥50 or 100 times, saving project cost

PVC plastic formwork can be re-used ≥50times with timber system, and ≥ 100times with metal frame system which is popular in most international construction structure.

02. 100% waterproof

PVC plastic formwork is 100% waterproof. Even if completely immersed in water, will not be deformed by the damp, not swell, also will not rust decay. The project can be conducted under the raining or snowy weather.

03. Flameproof and high temperature resistance

PVC plastic formwork is B2 grade antiflaming and high temperature resistance. Within

-40℃ to + 70 ℃ temperature, it doesn't shrink, not crisp, no crack, non-deformation. So, it can be used for any type of cement concrete, and can be outdoor exposure to the sun and snow.

04. Smooth surface, no need plastering, no need releasing agent.

The surface of PVC plastic formwork is smooth always even after using for tens of times, so the finished so no need to spay releasing agent before application. And also the demoulded wall surface is glossy, so no need plastering again.

05. High strength, excellent shore hardness

PVC plaster formwork has Shore hardness up to over 85, much higher than required standard. It can hold 2.5tons/m³ concrete weight, almost available for any application, such as commercial , residential , office ,bridge, tunnel, etc. Resistance to hit and fall off, so it is difficult to damage during demoulding and construction.

06. Good tenacity and bending strength

PVC plastic formwork has high impact strength and bending strength, which is much better than the plywood formwork, wood formwork and steel/aluminum formwork. Even in winter, our PVC plaster formwork will not be crisp. Don't worry about the breaking during construction.

07. Stable project quality

As PVC plastic formwork doesn't stick concrete, so even after re-using for 50times or 100times, its surface is still smooth. Therefore, demoulded wall surface is same premium from 1st floor to top floor. Quality stability meets with high-end project standards, avoiding the problem of plywood formwork and unqualified plastic formwork

08. Don't delaminate during construction

PVC plastic formwork adopts the advanced foaming technology, not pressing and lamination, it never delaminates from beginning to finally being wasted, completely avoid the same problem of plywood formwork.

09. Strong variability and adaptability

PVC plastic formwork can saws, planks, drills, nails, can be cut into any geometric shapes at will, meet various building shapes needs.

10. 100% recycle, high recycle benefit and environment friendly

The PVC plastic formwork can be 100% recycled, so saving lots of forest resources. This performance meets with the world environmental trend, will be more and more welcome by construction field. Also you can sell the used PVC plastic formwork to other factories with much higher cost than plywood formwork, to get higher recycle benefit.

11. No need demoulding agent, easy to demould , easy to clean,

PVC plastic formwork doesn’t need to spay the releasing agent before application, so can save the agent cost and labor cost. Also hardly stick concrete during construction, so it is lightweight all the time, easy to demould by hands and clean quickly, just use mop and water.

12. Long service time, no need special curing

PVC plastic formwork is corrosion resistant, acid resistant, alkali resistant, so no need special curing.

If change to the PVC plastic formwork, you can save following cost:

1. Can re-use over 50times with timber system, and over 100times with metal frame system. It means 1 piece of PVC formwork ≥ 5 or 10 piece of plywood/timber formwork, saving formwork cost .

2. No need demoulding agent before application, saving agent cost .

3. No need secondary plastering after demoulding, saving much labor cost and plastering cost.

4. Same project quality from 1st floor to top floor, saving labor cost to fix up defects.

5. 100% recyclable. You can sell used PVC formwork with a much higher price, to get higher recycle benefit.

6. Easy to clean, just use a mop with water to clean the used PVC formwork, saving labor cost.

7. Excellent strength, not easy to break during construction, saving formwork cost.

8. 100% waterproof, no need to worry about rust/deformation/swelling, etc. saving formwork cost .

9. Using foaming technology, won’t become crisp in the winter, saving formwork cost .

10. Never delaminate, saving formwork cost .

11. Doesn’t stick concrete , always lightweight, reducing working strength.

Multiple application:

1. External & Internal Wall Formwork.

2. Square & Round Column Formwork

3. Slab Formwork

4. Stair Formwork

5. Other Special Application

- formwork

- plywood formwork

- steel-ply formwork system

- PVC plastic formwork

Production Capacity:

6000

Delivery Timeframe:

Depends on Size of Order

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

FOB - Free on Board

Packaging Details:

pallet or bulk loading

More about

Shandong Jingfang Import and Export Co. , Ltd

50-100

Employees

500K - 1M

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

Keywords

- Building formwork

- Scaffolding

Contact and location

-

Grapho Wu

-

+86 539 xxxxxxxx

-

Linyi / Shandong | China