Description

Production capacity: 11t/h

Particle size range: D50:2 to 45 m

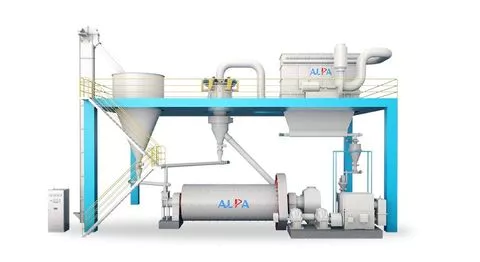

The whole production line mainly includes crushing (generally using two segments of broken), grinding, grading, packaging, magnetic selection, transportation, lifting and so on.

After the material is roughed, the ball mill is added by the controllable feeding device, the grinding medium in the mill by virtue of the dynamic energy obtained when the grinder rotates repeatedly impacts, grinds and crushes the material, and the crushed material is exhausted by the ball mill tail to inhale. Inside the tank, from negative pressure to the internal grading machine for grading, qualified fine powder by the cyclone collector or dust remover collection, after grading of the coarse particles from the lower end of the grader discharged, through the transmission tube re-entered the ball mill for crushing.

- Powder ball grinding grading production line

Production Capacity:

1000

Delivery Timeframe:

Within 60 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

CPT - Carriage Paid to

DAF - Delivered At Frontier

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

DEQ - Delivered Ex Quay

DES - Delivered Ex Ship

EXW - Ex Works

FAS - Free Along Ship

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

Not informed

More about

ALPA

100-200

Employees

10M - 50M

Sales volume (USD)

20%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Representative / Agent

- Distributor / Wholesaler

- Business Service

- Retailer

Keywords

- Ultra-fine powder grinding crushing equipment.

Contact and location

-

Luanne ********

-

+86 53********

-

潍坊市 / 山东省 | China