Description

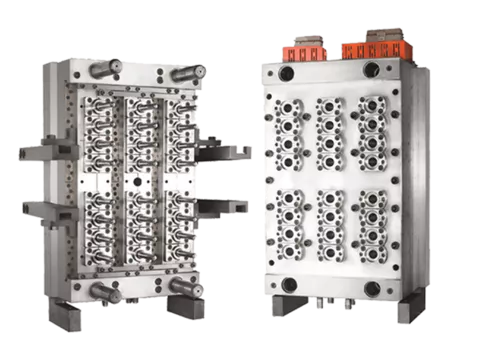

Cap Mold Feature

1. Adopt imported steel P20, Germany 2316, S136 etc.

2. Each cavity and core have independent cooling system, BeCu add in the core of mold, shortening production cycle time.

3. Rational mold design to extend mold life and get high production efficiency.

4. Mirror hand polishing and mold plates chroming to create added-value.

5. Precision Machining to ensure high production efficiency & fine parting line effect.

6. Skilled Language in communication and experienced in international standard.

7. Hot runner system: China advanced brand or imported hot runner system brand.

Each cavity has independent temperature control and heater system.

8. Anti-theft cap mold or based on customer's design.

- 24cavity plastic cap mould

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

CIP - Carriage and Insurance Paid to

Packaging Details:

Not informed

More about

Taizhou Shunke Moulding Co., Ltd

500-1000

Employees

0 - 100K

Sales volume (USD)

10%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

Keywords

- China PET Preform Molds

Contact and location

-

semi ********

-

+86 1********

-

Taizhou / Zhejiang | China