Description

Graphite crucibles play a vital role in various industries such as metallurgy, foundry, jewelry manufacturing, etc. These crucibles are essential for melting, casting, and refining metals at high temperatures.

Classification of graphite crucibles: Crucibles can be divided into three categories: graphite crucibles, clay crucibles, and metal crucibles. As a leading supplier in China, Yida specializes in manufacturing two types of graphite crucibles: machined graphite crucibles and graphite clay crucibles.

Due to different properties, uses and environmental conditions, its raw materials, production methods, technologies and product specifications also differ. Natural crystalline graphite is used as the main raw material for graphite crucibles, so that it retains the physical and chemical properties of natural graphite. These crucibles have excellent thermal conductivity and high temperature resistance. They have a low coefficient of thermal expansion in high-temperature applications and are resistant to strain in quenching environments. In addition, graphite crucibles exhibit significant chemical stability in acidic and alkaline environments, exhibiting strong corrosion resistance. Graphite crucibles are available in a wide range of sizes, regardless of the scale, quantity, or material to be smelted. They can be manufactured in any size and quantity while guaranteeing the purity of the smelted material. Because of its superior properties, graphite crucibles are widely used in metallurgy, casting, machinery, chemical and other industrial sectors to smelt alloy tool steel, non-ferrous metals and their alloys. They provide significant technical and economic benefits.

Machined graphite crucibles

Machined graphite crucibles, also known as high-purity graphite crucibles, are mainly processed from high-purity and high-density graphite materials, such as molded graphite materials, isostatic graphite materials, etc. These crucibles are customized to the customer's specifications. Depending on the molten material, machined graphite crucibles can be further divided into molten steel crucibles, molten copper crucibles, molten gold crucibles, and analytical crucibles. In addition, we can produce graphite arcs for a wide range of applications.

Gold refining crucibles: Crucibles used to melt gold require high-purity and high-density raw materials. The bulk density should be greater than 1.85g/cm3 and the total ash content should be less than 50ppm. Molten gold crucibles are typically machined from high-purity, high-density, fine-grained graphite. The raw materials for these crucibles include molded graphite and isostatically pressed graphite.

Uranium salt refining graphite crucible: This kind of crucible is a large graphite crucible, and the common sizes are Ф400mm×700mm, Ф500mm×800mm, etc. The production process includes the selection of high-quality, low-ash petroleum coke, crushing, grinding, mixing, kneading, extrusion (or forming), roasting, multiple impregnation, graphitization and purification. The main raw material for these crucibles is isostatically pressed graphite material.

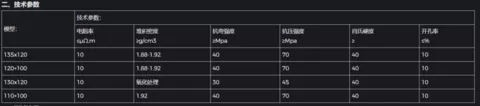

Graphite clay crucible

Graphite clay crucible, also known as SiC graphite crucible, is mainly composed of silicon carbide (SiC) and graphite. They are mainly used to melt copper, aluminum, and other common metals. These crucibles are relatively low-cost and offer a large molten metal capacity. The main forming method for these crucibles is pressure forming.

Important guidelines for crucible use:

Store the crucible in a dry place protected from rain. Before use, bake it slowly to 500 degrees Celsius.

The crucible should be filled according to its capacity to avoid excessive pressure, which can cause the metal to crack due to thermal expansion.

When removing molten metal, it is best to use a spoon and try to use as few calipers or other tools as possible. If tools are required, they should match the shape of the crucible to avoid excessive local stresses that could shorten the life of the crucible.

- Graphite crucibles

- high-purity graphite crucibles

- vacuum aluminized crucibles

- metallurgical crucibles

- crucible evaporation boats.

Production Capacity:

200000

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Not informed

More about

Hebei Yida Trading Co.,Ltd.

10-50

Employees

500K - 1M

Sales volume (USD)

100%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

- Business Service

Keywords

- Graphite material

- powder

- blocks

- rods

- mechanical parts

Contact and location

-

Du ********

-

+86 1********

-

Xingtai / Hebei | China